Cell phone motherboard repair in the use of stencil implantation of tin methods and precautions

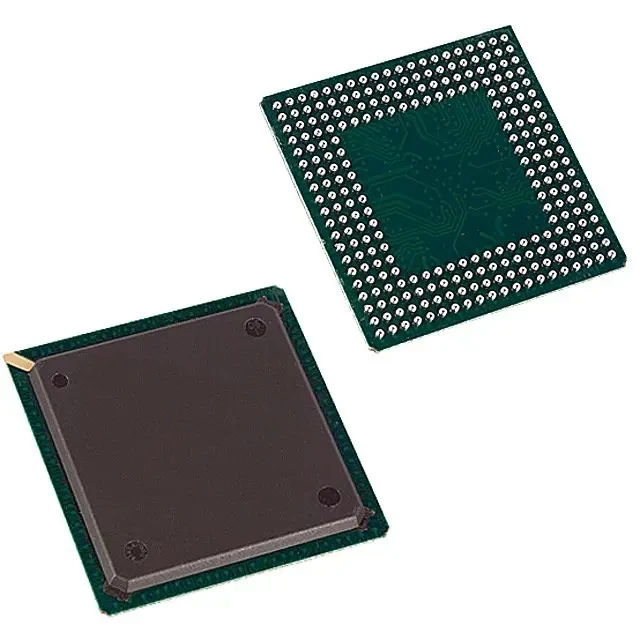

Today's cell phone motherboards are using BGA (Ball Grid Array) - Ball Grid Array packaging technology, high density surface mount packaging technology. This highly integrated package has a faster and more efficient way to dissipate heat, but also increases the difficulty of motherboard repair, after taking down the installation back, most need to re-tin. So the hands of repair masters are equipped with fast positioning BGA tinning table and tinning stencil, in the motherboard ball planting can accurately locate all tin points to improve efficiency.

The following we use the cell phone motherboard BGA rework as an example to detail the use of stencil to BGA chip tinning the whole process and precautions.

Translated with www.DeepL.com/Translator (free version)

Preparation: It is necessary to ensure that the tinning net and BGA chip are clean, clean, and clean again. Use lead-free board washing water with a small brush to clean, clean evenly so as not to damage the implantation net, and clean the implantation net after each implantation is completed.

For the removed IC, it is recommended not to remove the solder on the surface of the BGA, as long as it is not too large and does not affect the cooperation with the tin-planting steel plate; if there is a large amount of solder, you can add an appropriate amount of flux paste on the surface of the BGA, and use a soldering iron to remove the excessive solder on the IC (note that it is best not to use the suction line to suck, because if you use the suction line to suck, it will cause the IC's solder feet to shrink into the brown soft skin inside, causing difficulties in tin), and then use a lead-free wash water with a small brush to clean evenly. caused on the tin difficulties), and then wash the board with water.

The choice of solder paste directly affects the temperature setting of the hot air gun, solder paste is divided into low temperature (138 ° C), room temperature (183 ° C), high temperature (217 ° C) three, which is mainly based on the type of motherboard to choose. Heat gun temperature setting for the tin paste melting point temperature increase of about 150 ° C is appropriate.

Translated with www.DeepL.com/Translator (free version)

Hot air gun wind speed should not be too large, should be set between 2-4 gears (to the classic BST-858 spiral air gun as an example), hot air gun wind speed or temperature is too high will directly affect the effect of the tin paste into a ball, the temperature is too high will make the tin paste directly boiling and can not "into a ball", wind speed is too fast to cause the tin paste Too high a temperature will cause the paste to boil directly and not "ball", too fast a wind speed will cause the paste to not fully absorb the temperature.

After aligning the IC with the appropriate hole of the tin-planting board, you can stick the IC to the board with a sticker, or use a special tin-planting table to make it easier and faster.

After the IC is aligned, press the board firmly with your hand or tweezers, and then scrape the paste with your other hand to apply tin.

If the solder paste is too thin, it is easy to boil when blowing the solder to make the ball difficult, so the drier the paste is, the better, as long as it is not dry and hard to form a block. If it is too thin, you can use a napkin to press a little to absorb dry. Normally, you can pick some tin paste and put it on the inner lid of the tin paste bottle and let it dry naturally. Use a flat knife to pick the right amount of tin paste to the tin plate, scrape down hard, scraping and pressing at the same time, so that the tin paste is evenly filled in the small holes of the tin plate.

Note: The key to the paste is to press the solder plate, if it is not pressed so that there is a gap between the solder plate and the IC, the solder paste in the gap will affect the generation of tin balls.

When blowing the tin into a ball, the hot air gun should be blown sideways, according to the size of the chip to choose a similar size of the hot air gun nozzle, it is best to remove the hot air gun nozzle, side oblique direction to blow the tin into a ball.

BGA chip by the tin implantation network blowing tin into a ball, to be cooled 10s-20s, gently use tweezers or vibration tin implantation network to remove the chip after the completion of tin implantation, and then add the appropriate amount of flux to the chip, adjust the air volume and temperature of the hot air gun, with anti-static tweezers moderate clamping chip, hot air gun straight blowing chip, so that each formed tin ball to its own pad position, the tin ball The color changes to bright white silver can be. If blow soldering into the ball, found that some tin ball size is not uniform, or even individual feet not planted on the tin, you can first use a scalpel (must use a new blade) along the surface of the tin-planting board will be too large tin ball of the exposed part of the flat, and then use a scraper to tin ball too small and lack of feet in the small hole full of tin paste, and then blow again with a hot air gun can.

When dealing with chip pads, soldering iron with flux, soldering iron temperature at about 360 ° C, soldering iron head gently "float" in the pad above, do not use excessive force to damage the pad.

If you feel that all the solder joints are scraped, use the air gun to blow the solder joints round a little cooler after removing the chip, you can gently warp the four corners or use your fingers to pop the planted tin network, and finally a small amount of solder oil on the chip with the air gun to blow round and smooth.

If the size of the tin ball is not uniform, repeat the above operation until the ideal state. When replanting, you must clean and dry the solder plate.

When removing glue or excess tin, pay attention to cooling down the board and protecting the surrounding chips and components from damage.

When applying solder paste and heating the surface of the solder paste with a hot air gun, please pay special attention to the strength of pressing the solder-planting net, and make sure that the solder-planting board is in full contact with the chip without any extra gap.

The badly used solder-planting net can be half and half coated with solder paste and soldering, and the tweezers should be pointed to the middle and both sides of the solder-planting net, so that the success rate is very high.

Here BEST tools also recommend the new Apple motherboard tinning stencil and tinning table, so that you tinning repair with half the effort!