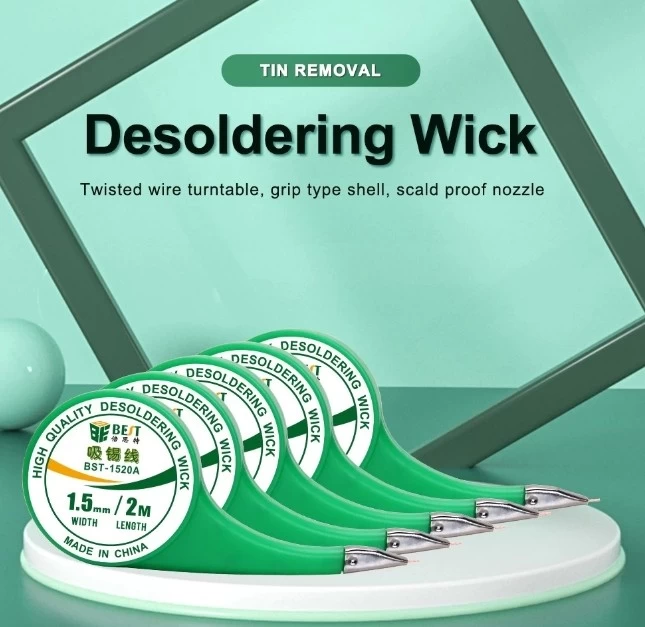

New Arrival, Quick Suction Tin Desoldering Wick!

A quick suction tin desoldering wick, also known as solder wick, is an essential tool used in electronics for removing excess solder from connections or desoldering components from printed circuit boards (PCBs).

Key Features of a Good Desoldering Wick

-

Material: Most desoldering wicks are made from copper or other conductive materials to ensure effective heat transfer and solder absorption.

-

Width: Available in various widths (usually from 1.5mm to 3.5mm). Choose a width based on the size of the solder joints you're working with; wider wicks can absorb more solder.

-

Flux Coating: A wick with a good flux coating will enhance solder absorption and make the process smoother. Flux helps the solder flow into the wick, making it easier to remove.

-

Heat Resistance: The wick should withstand the heat of the soldering iron without degrading.

-

Length: Longer wicks allow for multiple uses and can be cut down as needed for different jobs.

Tips for Using Desoldering Wick

-

Preparation: Place the wick over the solder joint you want to desolder, ensuring it covers the solder.

-

Heat Application: Use a soldering iron to heat the wick. The solder will be drawn into the wick as it melts.

-

Movement: Hold the soldering iron on the wick for a few seconds, then remove the iron but keep the wick in place for a moment to absorb any remaining solder.

-

Replacement: Once the wick is saturated with solder, cut off the used portion and use a fresh section for the next joint.

Using the right desoldering wick can significantly improve your soldering experience and efficiency. If you have any specific needs or additional questions about soldering practices, feel free to ask!