How to achieve sensor noise reduction design in smart car development

In recent years, with the spread of electric vehicles, the popularity of the ADAS (senior driver assist system),sensorThe application is getting wider and wider, and the noise environment has become more and more severe. The micro environmental signal of the sensor needs to pass the operationAmplifierwithComparatorsConvert to an electrical signal to be sent to the microcontroller (MCU) Calculate, soOperational AmplifierAnd the role of the comparator is increasingly important.

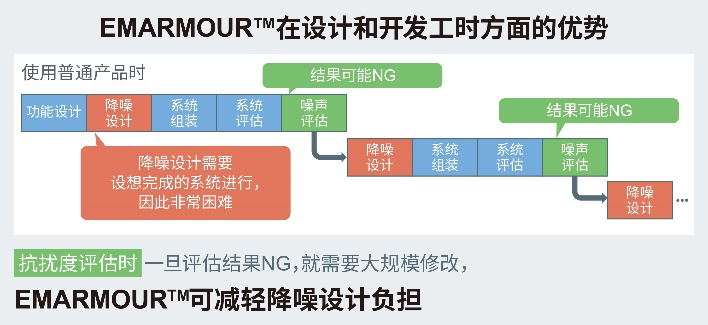

The problem is, usually in the automotive development, it is difficult to make noise assessment on the circuit board and system monomers. Generally, it is necessary to evaluate after the system is assembled. Once the evaluation result ng (not pass), it is necessary to make large-scale modifications, so noise reduction design It has always been a tricky topic.

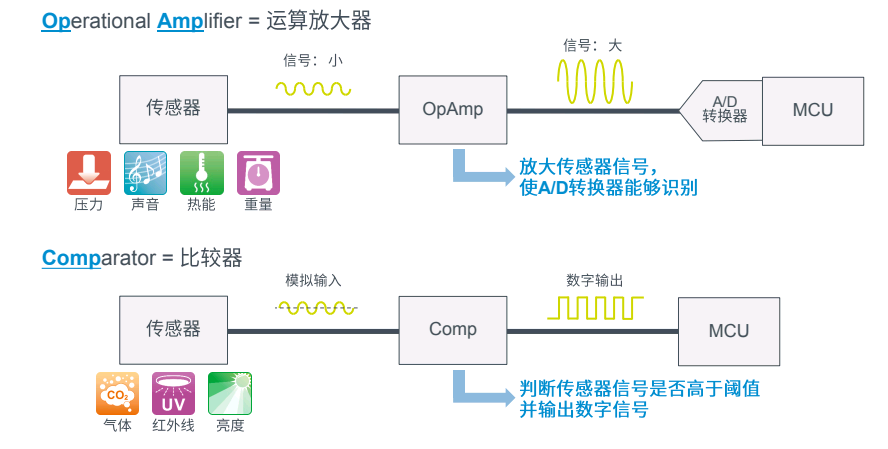

1. Operational amplifier and comparator and sensor

The operational amplifier is referred to as "op amp" is highly magnified.Circuitunit. In the actual circuit, a functional module is usually formed in conjunction with the feedback network. It is a specialcouplingCircuits and feedback amplifiers. Its output signal can be a mathematical operation result such as input signal plus, minus, or differential, integral.

The comparator is a circuit that compares an analog voltage signal with a reference voltage, and the output signal of the sensor can determine the signal or the like, output a digital (high / low) signal.

Sensor signal must be operated by operational amplifiers and comparators

The signal received by the sensor should be transmitted to the MCU implementation control through two ways. The first is to enlarge the small signal of the sensor to enlarge the small signal of the sensor, becomes the identified voltage level of the MCU and transmit to the MCU; the second is the threshold set by the comparator to determine the high and low of the sensor signal, and then transmit it to MCU.

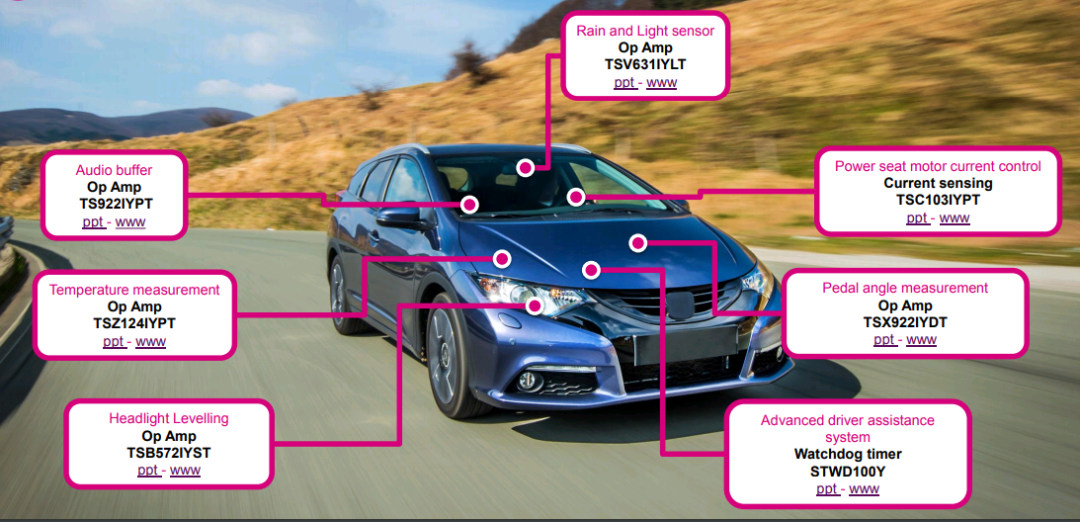

Vehicle operational amplifier application example

It can be seen that the different sensors need to be signal processing with the operational amplifier and the comparator, and finally transmit to the control unit, and then control the various modules of the vehicle by the control unit. How many sensors need to have many operational amplifiers and comparators, so the quantity is increasing.

In the in-vehicle application case, different modules use different op amps or comparators. With the development of ADAS and smart driving, more and more occasions in vehicles will use op amp or comparator.

2, high precision, low error is easy

Since the sensor is converted into an electrical signal, it is finally made by the MCU judgment signal, requiring operational amplifiers and comparators to ensure high precision and low errors to ensure amplification or comparison signals are reliable and can be utilized. of.

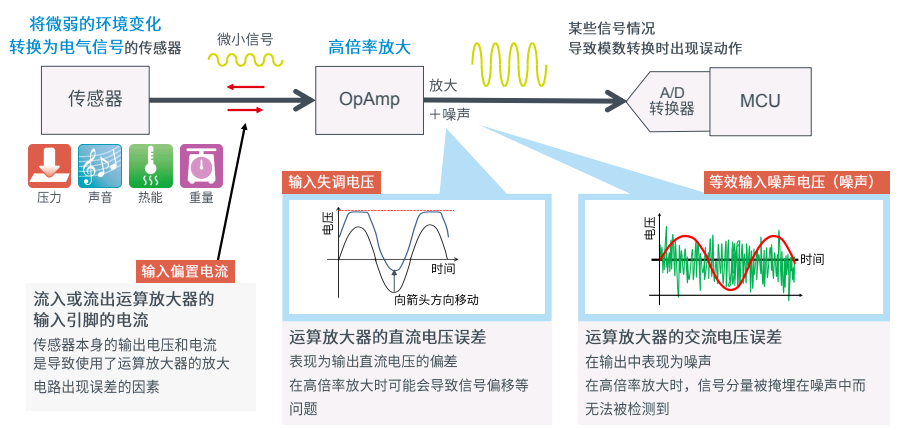

Operational amplifier is the key to improving sensing accuracy

3, noise also affects the sensing accuracy

Another factor affecting the accuracy of the sensor system is noise. It mainly comes from two aspects. The first is EMI (electromagnetic interference), that is, the noise generated by the IC itself may interfere with other electronic devices, bringing errors to the entire system accuracy. If the IC or system anti-EMI performance is poor, when noise interference is generated around,ComponentOr the system may cause malfunction, so you need to usefilter(Capacitor,ResistorWait) and shield (metal plate) to reduce noise. The second is the EMS (electromagnetic tolerance) characteristic, that is, the chip itself can withstand the noise interference from the outside. Therefore, the operational amplifier for sensor applications must have low noise and anti-interference performance.

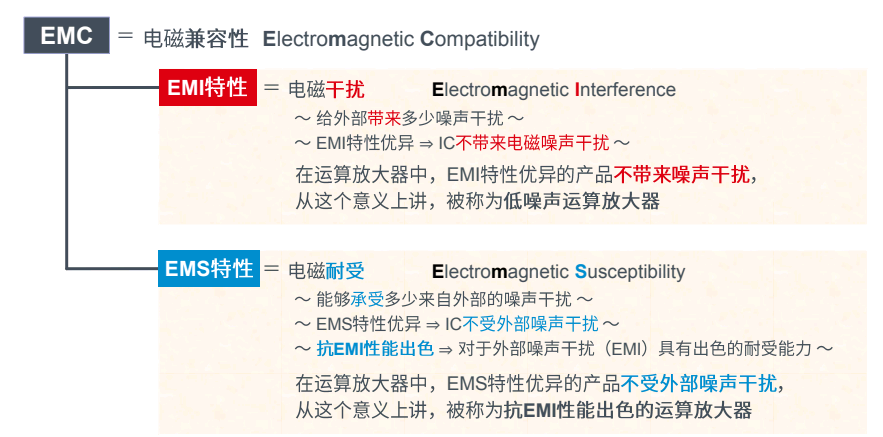

Noise related definition

EMC(Electromagnetic compatibility) means that the electronic device or system has the ability to resist electromagnetic interference, and does not produce excessive electromagnetic radiation.

Connotation of electromagnetic compatibility

4. How can I achieve low noise performance?

First, the internal noise of the operational amplifier can be roughly divided into flash noise caused by the process structure, and thermal noise generated by the circuit design. In order to reduce overall noise, by improving process and circuit design, the noise ingredients of the two aspects can be reduced to achieve overall ultra-low noise.

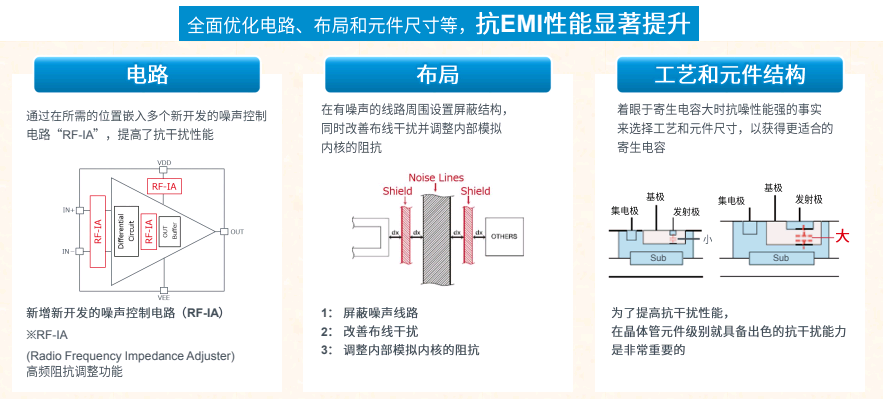

The anti-EMI performance can be significantly improved by comprehensive optimization circuitry, layout and component size, etc. There are three ways: First, the anti-interference performance is improved by embedding noise control circuitry in the desired position; second, set a shield structure around the noise, improvewiringInterference and adjust the internal simulation kernelimpedanceThird, focusing on the fact that the anti-noise performance of parasitic capacitance is strong, and select more suitable parasitic capacitors. These three points are done, and the anti-noise capacity of the entire chip is very strong.

Comprehensive optimization of overall noise

5, eliminate noise from solving electromagnetic radiation

Parameters affecting the accuracy of operational amplifier include input offsetCurrent, Input offset voltage and equivalent input noise voltage. By optimizing these parameters, the accuracy of the sensor system can be improved.

For the above challenges,RomaDeveloped from EMI performance from 2017 Excellent EMARMOUR (EM - Electromagnetic Radiation, Armour - Armor) Series Operational Amplifier Products. Its development is to prevent products from malfunction due to noise interference without taking special measures. In 2018, the series of bipolar products, a total of four, which help to reduce customer noise reduction design burden, and have gained a high praise in the car market.

Because of "Armor", 2020, Roma's op amp and comparator product shipments exceeded 500 million, of which the industry part accounted for 12%, and the car parts were as high as 25%.

EMARMOUR brand products integrate circuit design technology, layout technology, process technology advantages, for ISO 11452-2 international immunity assessment test, realize the excellent anti-interference performance of the output voltage fluctuation of the entire noise frequency band, which helps to solve system development Noise interference problem during the process reduces design workers and improves system reliability.

Improve system reliability

Roma launched four anti-interference performance CMOS (complementary metal oxide semiconductor) operational amplifier BD87581YG-C (single channel) and BD87582YFVM-C (dual channel), Its bias current, the conversion rate is greater than the previous generation bipolar product.

For example, electron radiation immunity implementation in the main planttestIn ISO 11452-2, in the entire noise band, the output voltage fluctuation of ordinary products is ± 300mV, and the new product is only within ± 10mV (1/30 of ordinary products). Therefore, when the new product is configured in the rear end of the sensor and other components, the use of the CMOS element structure can achieve fast and accurate signal enlargement, which is not affected by external noise, which helps to simplify the design of various abnormal detection systems, and improve their reliability. Sex.

New products solve the problems facing ordinary products in the following three aspects:

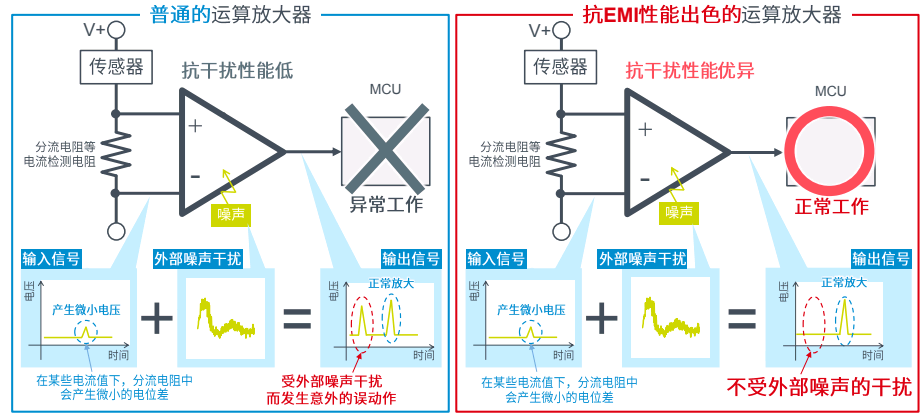

First, the input voltage in the sensor application is very weak. Due to the low anti-interference performance, the normal op amp product will be inferred by external noise, so that the MCU receives the error signal to cause an exception. EmarmouRTM series products using anti-EMI performance is not easily interfered with external noise.

Avoid external noise interference

Second, from the overall design process of the automotive electronics, the overall noise of the system is used to use ordinary op., And it is generally necessary to wait for the DEMO board to do an overall assessment. If the noise test results ng, it will spend more work. To reduce noise, even add countermeasures in the design, increase overall design workers. The EmarMourtM series has strong anti-noise capacity, which can effectively reduce the noise reduction design burden, help customers reduce system design workers and costs, and quickly respond quickly in shorter delivery cycles.

Third, as a measure to reduce external noise interference, ordinary opinion itself input, the output is added to add filtering device, the simplest is RC filter, that is, each port plusresistancewithcapacitance. Excellent noise reduction levels can be achieved without any filtering measures using the EmarMourtM Series. Simply put, using four-channel products can reduce up to 18 peripheral components, effectively saving customer-component costs and packages.

The new series of products meets the AEC-Q100 standard, including: EV / HEV carInverter, Engine control unit, ECALL (vehicle emergency call system), car navigation system, automotive air conditioning, etc .; industrial equipment (FA equipment), metering instruments,measuringEquipment, servo system, various sensor systems, etc., various types of car and industrial equipment with high noise reduction requirements.

6, op amplifier and comparator enhanced smart driving added value

Semiconductor (ST) The operational amplifier and comparator lineup is aimed at enhance the added value of smart driving using various vehicle devices. Its automotive-level products meet the requirements of super high reliability and quality, including: AEC-Q100 and Q101, TS-16949, PPAP (product approval procedure) Availability, Q002 EWS Statistics Analysis Guide (SYA) and Device Average Test (PAT) Guide, etc. The 100% heat test in the rear end (package and test) exceeds a specific screening and test method of the AEC-Q100 standard.

Enhance the op amp and comparator of intelligent driving added value

These products can be safely operated at extreme temperatures of -40 to 150 ° C for safe operation.enginecontrol,GearboxModules and security key systems; and can be integrated and easily integrated into signal adjustment,monitorAnd control solutions. As the perfect supporting chip of the microcontroller and analog sensor, its operational amplifier helps to enhance signal chain energy. Solutions such as micro DFN, QFN, SC-70, and 6-Bump CSPs, saving space for a limited space optimization of vehicle.

These products have a wide range of applications, includingAudioBuffer, temperature measurement, headlighting, rainwater and light sensor, electric seat motor current control, stepPlateDegree measurement, ADAS, etc.

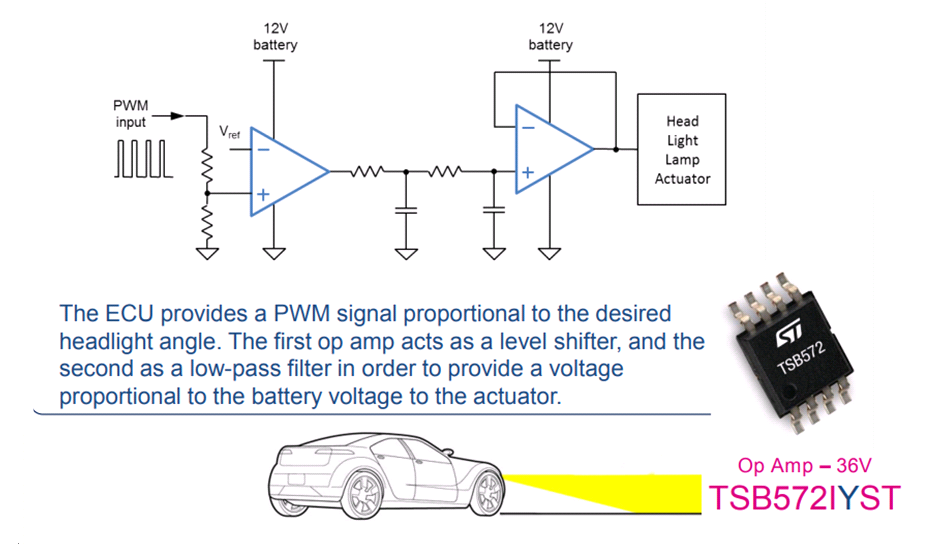

Take the top 36V TSB572 to see the function of this operational amplifier. Vehicle tire pressure, loading quality or road conditions will cause the vehicle's pitch angle to change, directly affect the illumination angle of the headlight; the leveling is becoming more and more important as the headlight power increases, to prevent other drivers Purpose.

TSB 572 can adjust and compensate for the dynamic pitch angle, using the PWM signal proportional to the desired headlight angle, and the first op amp is used as a low pass filter. In order to provide the actuator with the storagebatteryVoltage proportional control voltage signal. It is characterized by not need to use a load dump clamp, and the rail-to-rail input / output stage (the input and output voltage swing is very close), and the charge pump circuit is not required. The charge pump has its own shortcomings, the circuit structure is different, and there will be the following cases: First, the battery is low, the disadvantage is that the ripple noise is large; if you want to reduce the ripple noise, you should use a high voltage capacitor. Capacity voltagestressIt will increase; the third is balanced one and second, the disadvantage is that the circuit is complicated. The cost of the latter two programs will also increase accordingly.

Simplified ahead of the noise processing

In addition, TSB 572 is an operational amplifier of a 40V BICMOS manufacturing process with a DFN8 package. CMOSTransistorThe current is only consumed when switching the status, so it belongs to a low power device. BiCMOS is a bipolar and CMOS process simultaneously in the same device. The operational amplifier based on this technology has excellent GBW / ICC energy efficiency, and the power current-performance ratio is one-fifth of the standard op amp on the market. In addition, low input offset voltage and temperature drift below 6 μV / ° C help simplify system design without fine-tuning or calibrating, ensuring stable performance within the rated temperature range.

Normally, the wider bandwidth is wide and the stronger the noise. When the system receives the noise signal, the noise energy can be reduced by the extended bandwidth to the entire bandwidth, thereby reducing the noise energy on the unit bandwidth. TSB572 is equipped with rail-to-rail input and output, gain bandwidth volume (GBW, index of evaluation amplifier performance) is 2.5MHz, and the maximum input offset voltage is 1.5mV. The device is stable during capacitive load, and the phase reversal protection is excellent. Wide power supply voltage of 4.0V to 36V can use a variety of power supplies to obtain rated parameters.

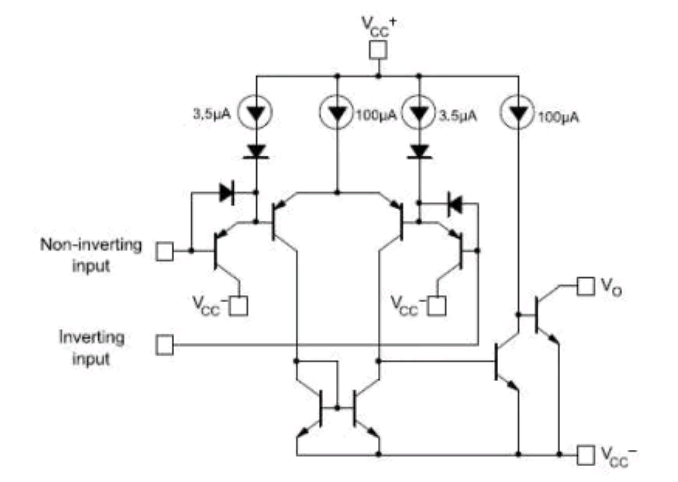

By the way, the ST comparator is said. The rail-to-rail input 1.8V high-speed comparator TS3021H is also -40 to 150 ° C wide temperature range, propagation delay 38ns, has a high speed response time. When the power supply voltage is 2V to 5V, the comparator can work in a wide temperature range. Ts3021h is less than 73μA, thereby having excellent power consumption and response time, meeting the automotive application requirements.

TS3021H schematic